Railroad Lube Filters

- Swirl Flow Design — Filtration Systems' patented Swirl Flow™ depth elements are a dramatic break-through in filter technology. By alternating layers of low and high density media, and balancing the ratio of circumferential to radial flow, the media layers progressively load with dirt, like peeling an onion. The result is an incredibly long-life filter, designed for reliable performance at low cost. Our depth filter elements last longer and perform better than pleated paper elements.

- Cotton Media — Cotton's fine fiber diameter anthophyllite properties make it an ideal medium for hydrocarbon filtration. We use only natural cotton fibers (not textile waste) in our products

- Local Wood Fiber — Wood absorbs water and acids (extending lube oil drain intervals) and improves the filter's flow characteristics. Our wood is grown and processed here in Wisconsin, for excellent cost control.

Call Us Today! 262-548-6210

Request a QuoteDescription

Filtration Systems’ patented “Swirl Flow” technology is a breakthrough in depth filter design, providing exceptionally long life, high efficiency, and low restriction to flow. “Swirl Flow” locomotive oil filters combine high efficiency and long-life with moisture removal to reduce acid and sludge build-up. 180-day service intervals increase productivity and reduce maintenance costs.

Our high-flow railroad lube filters have been use for years in demanding conditions, often over mountainous terrain. They consistently last a minimum of 3 months, and often 1/2 year, between filter change-outs We have manufactured hundreds of thousands of railroad lube elements, protecting locomotive engines worldwide, with the best value in the industry.

Filtration Systems’ lube filters fit all standard EMD, Alco and G.E. locomotives.

Technical Overview

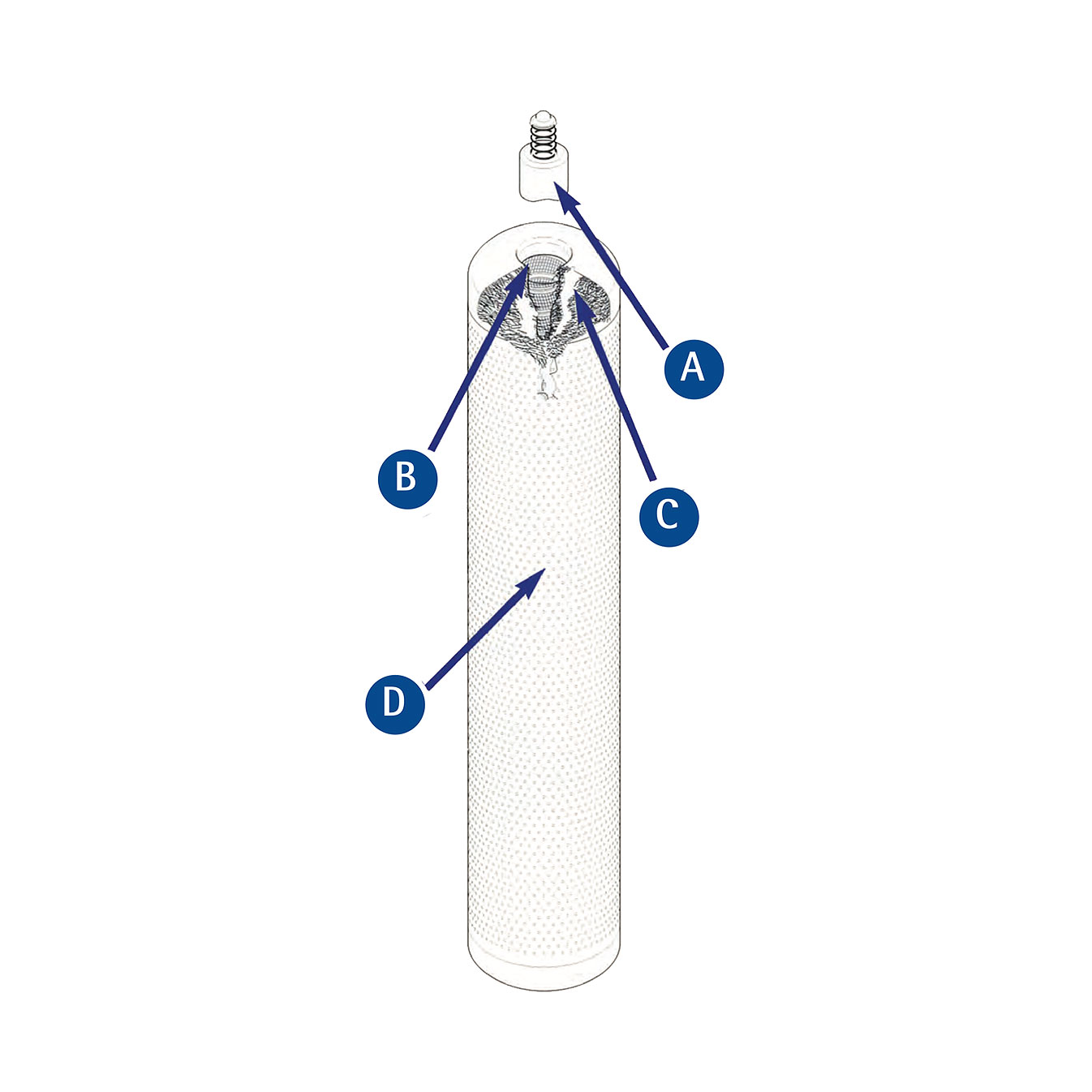

- A

Different end-configurations assure direct interchangeability with EMD, G.E., Alco and Bombardier locomotives.

- B

High-strength spiral lock seamed center tube prevents collapse. Easily removed and recycled. Made in-house for cost control.

- C

Our patented “Swirl Flow™” media, the secret to long service life. Only available from Filtration Systems, an exceptional value!

- D

Outer perforated wrap for flow diffusion. The filter has no side seams or end caps