Coalescing Fiberglass Filters

- Wrapped Center Tube — Our core wrap prevents media migration so that abrasive fibers do not get released from the filter.

- Metal End Caps — Filtration Systems uses metal end caps so our filters are sturdier than competitors who use plastic caps (or don't use caps at all).

- Buna or Viton Gaskets — Our gaskets are 100% highest quality. We offer an assortment of gaskets that fit the necessary process conditions of your application.

- Fiberglass Media — Fiberglass media was considered a breakthrough in filtration technology when it was first introduced, because of its unique combination of high removal efficiencies and high permeability. Microglass fibers have very fine diameters, resulting in more void space, thus providing greater dirt-holding capacity and increased flow rates.

- Fibers have high surface charges — enabling them to attract polar compounds, such as water, out of hydrocarbon process streams. This "wettability" makes fiberglass filters effective coalescers, removing water and other liquids from refined product and natural gas.

- Fiberglass gas filters have extensive use — in such diverse applications as gas gathering, dehydration units, sweetening plants, tail-gas treaters, industrial gas separation, sewage, landfill and digester gas, and cogeneration facilities.

- We use molded seamless bonded tubes — instead of slit unbonded pipe insulation. This results in better filtration performance without bypass.

Call Us Today! 262-548-6210

Request a QuoteDescription

Filtration Systems makes a wide range of fiberglass filter elements for natural gas purification. Our media is molded into seamless tubes and reinforced with phenolic resin (a distinct improvement over some competitor’s “pipe insulation”). Natural gas is often dirty, wet and corrosive, and gas filters have to withstand liquid slugging and abrasion from pipe scale. Our cartridges use high efficiency seamless fiberglass tubes, reinforced with a spiral lockseamed center tubes for high collapse strength. Cross references to PECO, Peerless, King Tool, Jonell, Flo-Line and Banner.

Since these filters are often installed ahead of large compressors, they must be designed to withstand vibration, pulsation, and abrasion from pipe scale and liquid slugging.

Our center tubes feature a spiral-lockseam construction for high collapse strength, and the metal is plated for corrosion resistance. The end caps are bonded to the media and center tube with a high-strength adhesive.

We use a polyester core-wrap to prevent media migration, as fiberglass fibers are very abrasive. Regrettably, some of our competitors don’t use core wrap!

For applications where iron sulfide is a problem, we offer a polyester membrane core

Technical Overview

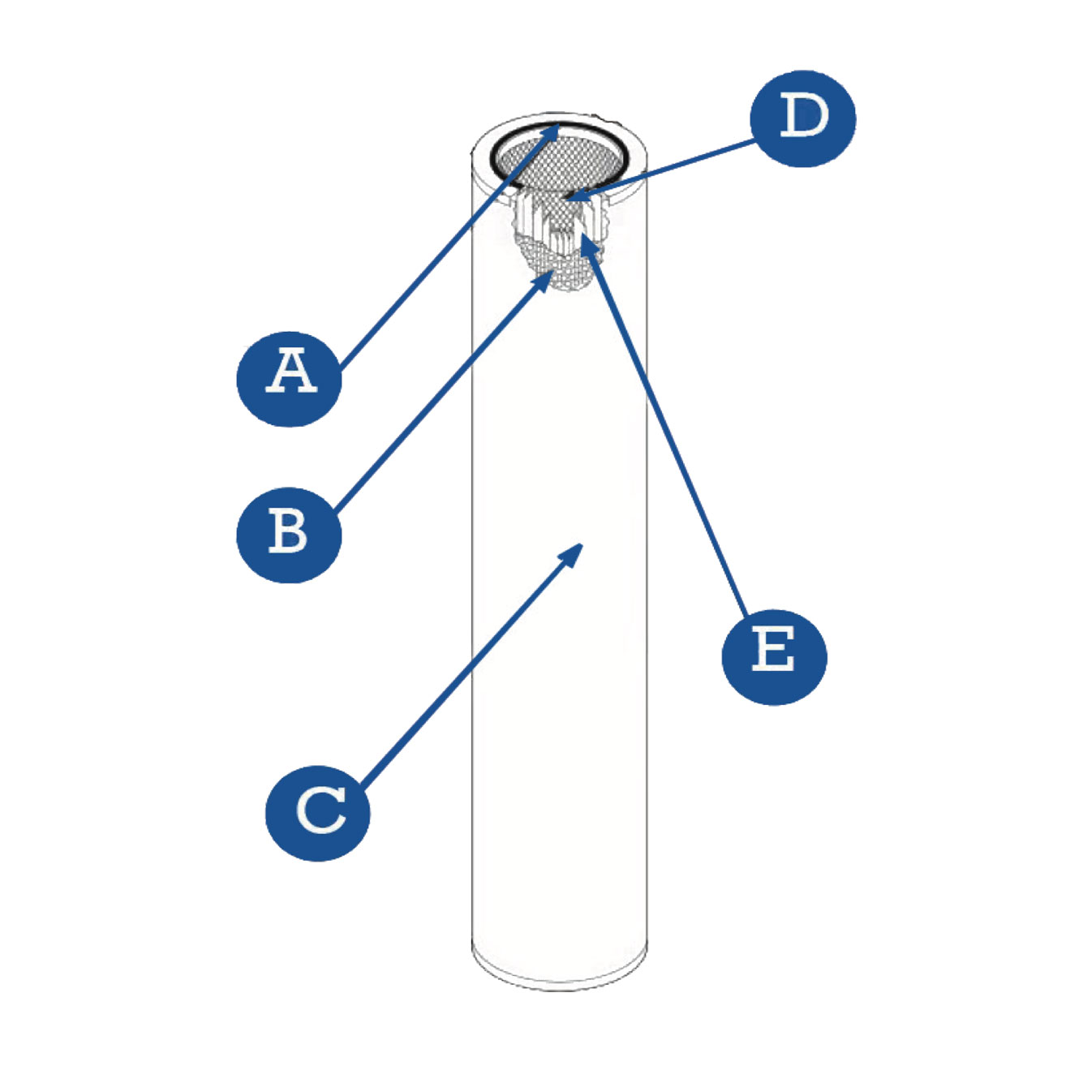

- A

Tin-plated metal end caps are bonded to the center tube for added strength. Choice of Buna-N or Viton gaskets.

- B

Double-louvered center tubes provide low flow restriction. Made in-house for excellent availability and cost control.

- C

Spun-bonded polyester core wrap prevents media migration. Available membrane wrap provides .3-micron protection.

- D

Molded seamless 6# fiberglass media removes particulates >1u and coalesces liquids for clean, dry natural gas.