Applications

Who Buys Filtration Systems, Inc. Products?

Filtration Systems Inc. (FSI’s) range of filters are utilized in the following: biogas filtration, dust collection, natural gas filtration, railroads, and stationary engines. These critical filters are utilized across the globe in a variety of industries to optimize the flow of various fluids and gases essential to modern life and society.

Natural Gas Filtration

FSI Filters eliminate impurities such as pipe-scale, iron sulfide, hydrates, water, hydrocarbons, sulfur, and carbon dioxide that must be removed before it is deemed “pipeline quality”.

Details

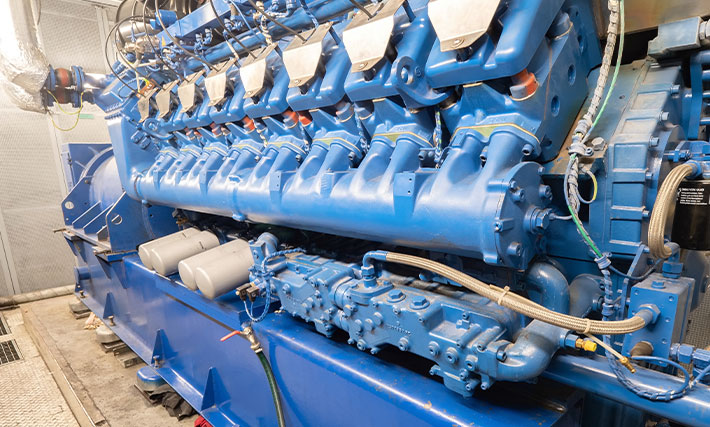

Stationary Engines

Filtration Systems has been making filters for large stationary engines for over 30 years. It is our core business.

Details

Railroads

Our long-life railroad lube and air-intake filters have been used for years in demanding conditions, often over mountainous terrain.

Details

Biogas Filtration

Filtration Systems makes specially-designed air, oil and fuel-gas filter for engines, compressors and generators that meet or exceed the unique and demanding requirements at biogas installations.

Details

Dust Collection

Filtration Systems makes a wide range of dust collect cartridges to fit all popular makes and models of equipment. The cartridges feature heavy-duty construction to withstand rigorous use. We offer three grades of media, to match your application requirements.

Details

Cabin Air Filtration

Filtration Systems makes a wide variety of panel-type cabin air filters for off-highway vehicles. Construction equipment, mining trucks and agricultural machinery all have operator cabs for roll-over protection.

Details

Powder Coating

Filtration Systems services the Powder Coating industry with a broad range of powder coating overspray filters. We make a variety of sizes and fit-up designs to fit most powder coating spray booths. These filters capture the powdered paint from the exhaust air stream.

Details